I will present a paper on this subject at

ASNE Day 2015: Engineering America’s Maritime Dominance

March 4-5, 2015 in

Arlington, VA

Military Jet Boats Now Dominant, but Not Sustainable

Valued for their high speed capability and shallow draft, marine jets beat out propellers as the dominant propulsion in commercial and military craft, even though jets consume more fuel at lower speeds. Yet lower speeds are where they spend most of their time.

Office of Naval Research

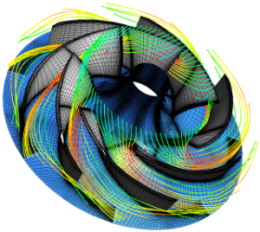

Water Jet Pump CFD

Automotive and Aircraft Technologies to the Rescue

By incorporating technology from modern aircraft and cars, jet boats can be much more fuel efficient at low and mid-range speeds without sacrificing high-speed capability or the other operational advantages of current technology.

Simulation Saves Time and Money.

My technical paper and presentation also demonstrate the incorporation of variable geometry and electronic controls in computer simulations to test systems and accurately predict performance. The models developed in this process are directly useful in rapid prototyping.

The graphic above is an example of the development of a marine jet pump using computational fluid dynamics.

My technical paper details computer design and simulation methods, which allow fast, accurate and economical prediction of performance and fuel consumption in any operational profile. The process produces files for use with the latest part prototyping and pilot production methods.