Never Bet Against a MicroController

Marine propulsion has lagged behind other transportation products because it has failed to integrate new technologies to produce innovative benefits in sustainability, safety, reliability, operating costs, manufacturing costs and lifetime ownership costs.

Marine propulsion has lagged behind other transportation products because it has failed to integrate new technologies to produce innovative benefits in sustainability, safety, reliability, operating costs, manufacturing costs and lifetime ownership costs.

These failures stem from routine reliance on familiar methods of product design, development and manufacturing. Doing it the same old way is comfortable, but produces too much of the same old results.

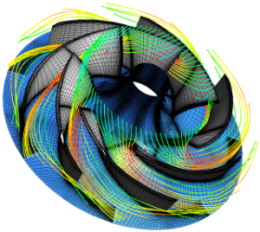

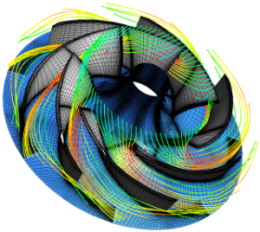

Simulation for Performance & Efficiency

Example of computational fluid dynamics (CFD). Image Courtesy of Pointwise. www.pointwise.com

How different would it be if marine propulsion design was not limited by these familiar product design, development, and manufacturing processes?

Let’s say the design process made maximum use of computational methods and simulation to define the mechanical dimensions and requirements of the optimum propulsion system over the expected range of operating speeds and loads.

If motor efficiency, lower emissions, and longer operating life require a variable power transmission as they do in trucks, buses and cars, why not make that part of the design?

It seems natural that such a system would be best made using design, development and manufacturing methods commonly used for autos, trucks, and large construction equipment.

Fortunately, these methods and services are highly developed, widely available, and ever more economical, which makes this whole approach more practical than traditional methods.

Why Not Boats?

Electronically controlled components, similar to those long found in aircraft, automobiles, and even home appliances, can enhance marine propulsion.

These controls, programming methods, and associated development services are readily available. This development path is highly automated for very large markets, so is the fastest, most exact, and most economical one available.

The only remaining question is

why has it taken so long for marine propulsion to get here?

Like this:

Like Loading...